JMRI: OperationsPro™

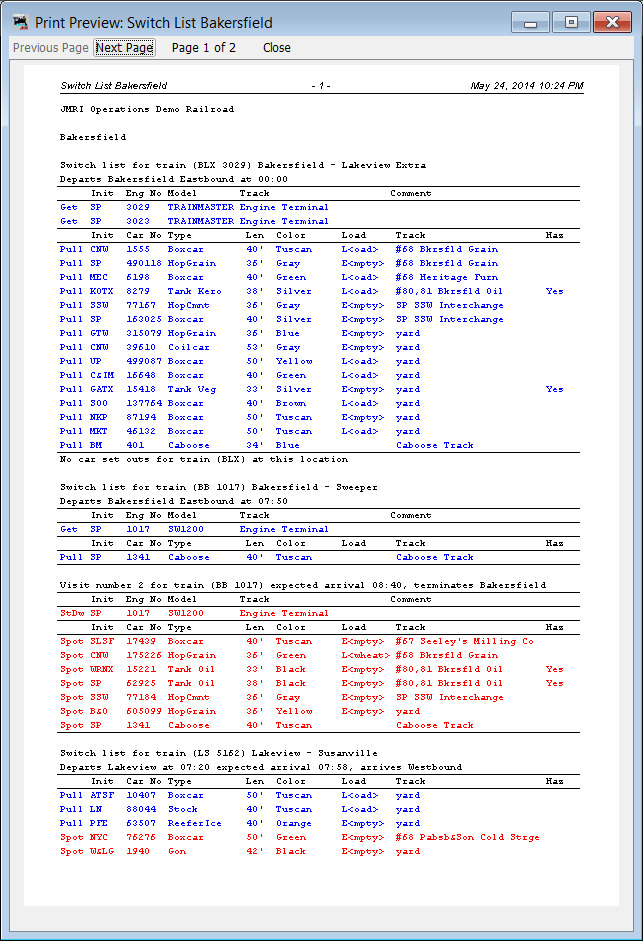

The JMRI Operations program allows you to create computer generated train Manifests for your railroad. A train Manifest details the work that a crew will perform during an operations session. The Manifest provides a list of car pick up and set outs and shows where the cars are located and where they should be eventually positioned on the railroad. The program allows you to enter a roster of cars and locomotives, define locations (stations) on the railroad, and routes for trains to travel. The car roster includes information about the car, including road, number, type of car, color, length, weight, load, date built, and owner. Trains are assigned routes that define locations or stations where cars can be picked up or set out. Features include the ability to control what car types, roads, and car loads a train, location or industry can service, the available track space for a location, and the maximum length the train can be between any two locations in the train's route.Locations can have spurs, yards, staging and classification/interchange tracks. Spurs are used to service industries, and can optionally have schedules assigned to them which allows for very fine and realistic control over car movement and loads. Trains can be configured to require a caboose or car with Flashing Rear End Device (FRED). The program generates Manifests for each train and switch lists for any location. A switch list for a location shows the work for all of the trains that will visit that location. The program can also place icons representing trains on a JMRI panel. The icon can be taught to move in the panel along with the train from location to location.

OperationsPro™ lets you create realistic prototypical car movements through the optional use of railroad divisions. Cars are returned to their home division when their loads are removed, or when a new load is provided by an industry in a foreign division.

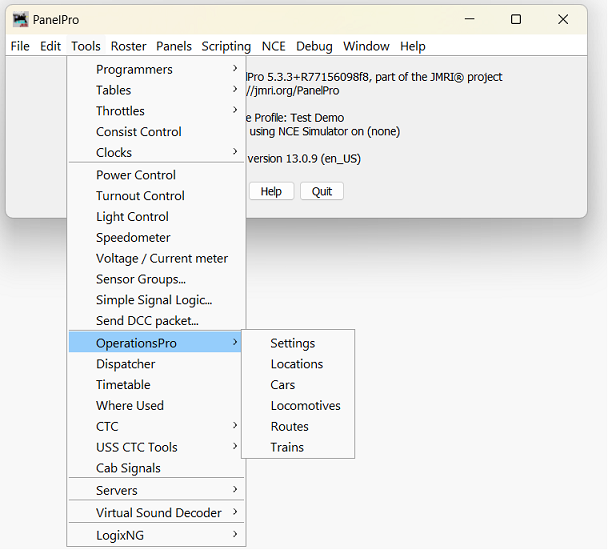

OperationsPro™ is included in the JMRI suite of Tools and can be found under the main menu heading "Tools⇒OperationsPro".

Table of Contents

- New User Advice

- Display and Help

- Multiple Layout Support

- Operation Files

- Operations Demo Files

- Quick Start Help

- Trouble Shooting and Diagnostic Tools

- Settings

- Panel Options (Train Icons)

- Backup

- Restore

- Settings Tools

- Options

- Manifest Print Options

- Manifest Printer Font

- Format

- Orientation and Paper Size

- Print on One or Two Sides

- Text Color

- Manifests and Switch List Options

- Add Logo

- Misplaced Cars Comment

- Hazardous Comment

- Manifest Print Options Tools

- Edit Manifest Header Text

- Edit Manifest Text

- Edit Switch List Text

- Build Report Options

- Backup to Directory

- Restore from Directory

- Manage Auto Backups

- Load Demo Files

- Reset Database

- Locations

- Add or Edit Location

- Train Direction Serviced

- Railroad Divisions

- Rolling Stock Serviced

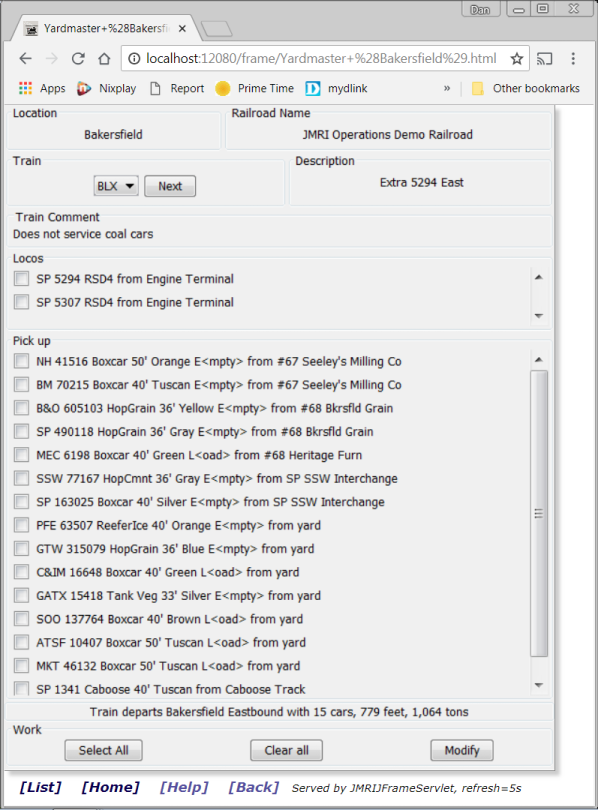

- Yardmaster

- Location Tools

- Yards

- Spurs

- Restricting Track to Certain Trains or Routes

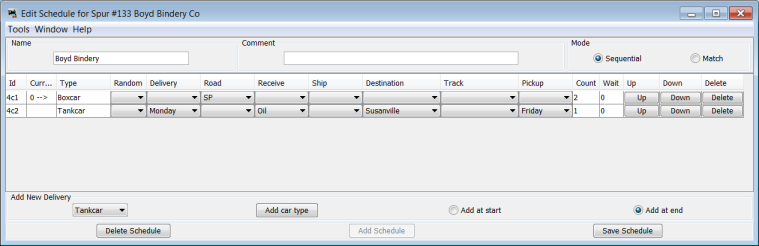

- Schedules

- Schedule Mode (Sequential or Match)

- Schedule Example

- Purposely Moving Cars Using Schedules and Loads

- Controlling Cars to the Spur / Industry

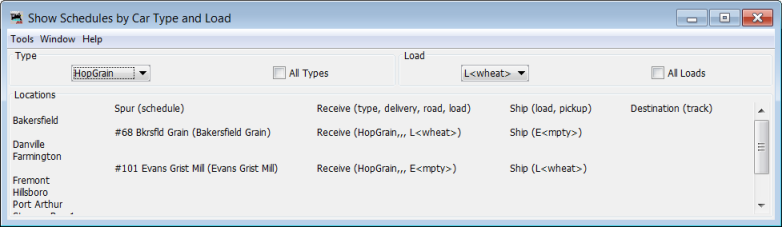

- Show Schedules by Car Type and Load

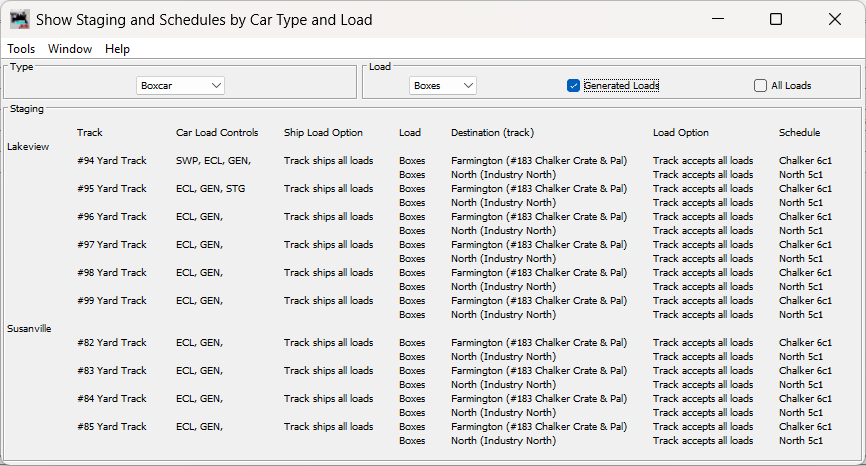

- Show Staging and Schedules by Car Type and Load

- Alternate Track or "Off Spot"

- Load Options

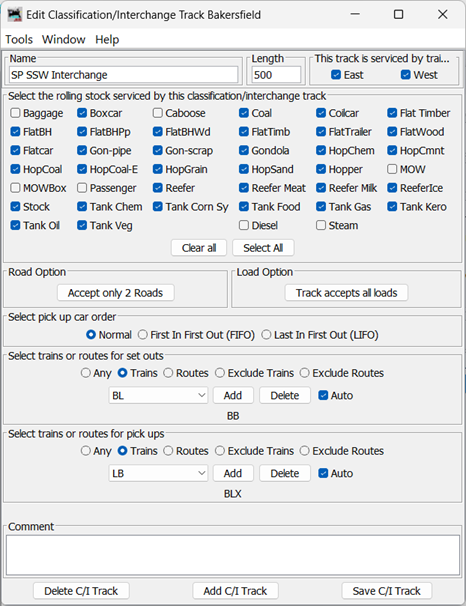

- Classification/Interchange Tracks

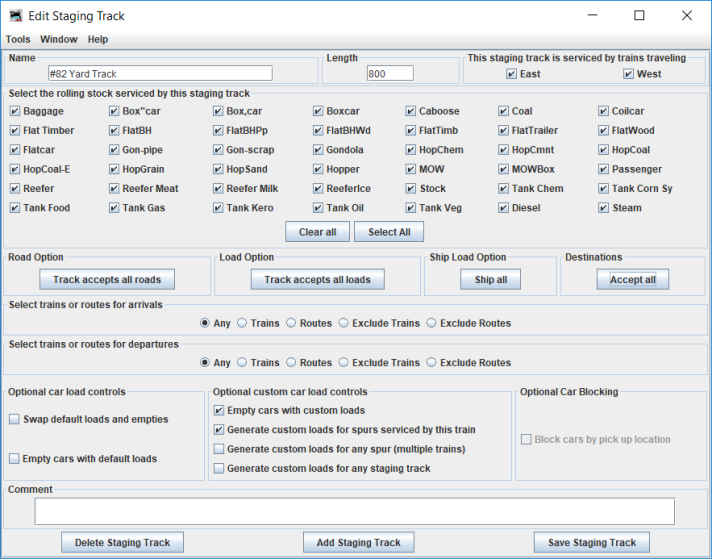

- Staging Tracks

- Track Tools

- Locations Tools

- Copy Location

- Copy Track

- Schedules

- Modify Locations and Tracks by Car Type

- Modify Locations and Tracks by Car Load

- Export Locations

- Import Locations

- Show Cars

- Show Locomotives

- Show Trains Servicing Location and Track

- Show Routes Servicing Location

- Print or Preview

- Print Locations

- Print Schedules

- Print Comments

- Print Location Details

- Print Track Analysis

- Print Track Error Analysis

- Cars

- Locomotives

- Train Routes

- Trains

- Add or Edit Train

- Reset Train

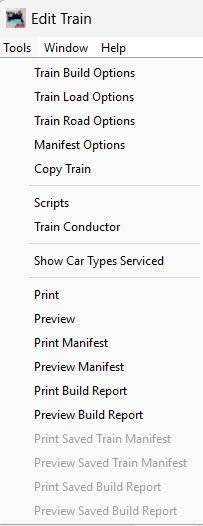

- Edit Train Tools

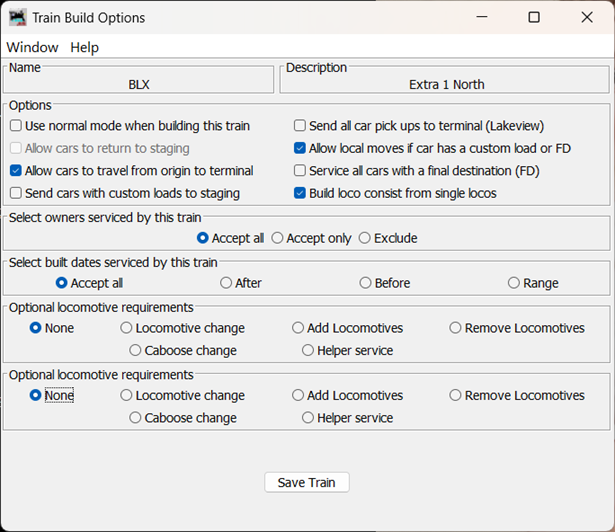

- Train Build Options

- Use normal mode when building this train

- Send all car pick ups to terminal

- Allow cars to return to staging

- Allow local moves when a car has a custom load or FD

- Allow cars to travel from origin to terminal

- Service all cars with a final destination

- Send cars with custom loads to staging

- Build loco consist from single locos

- Train Owners

- Train Built Dates

- Locomotive or Caboose Changes en Route

- Train Load Options

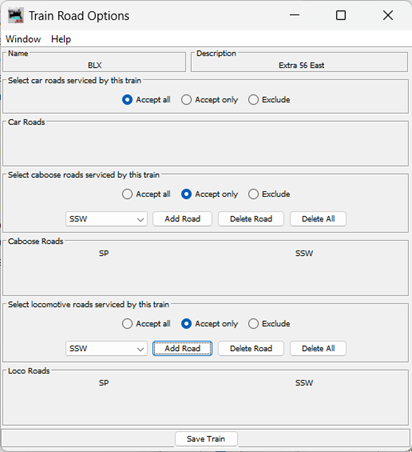

- Train Road Options

- Train Manifest Options

- Copy Train

- Scripts

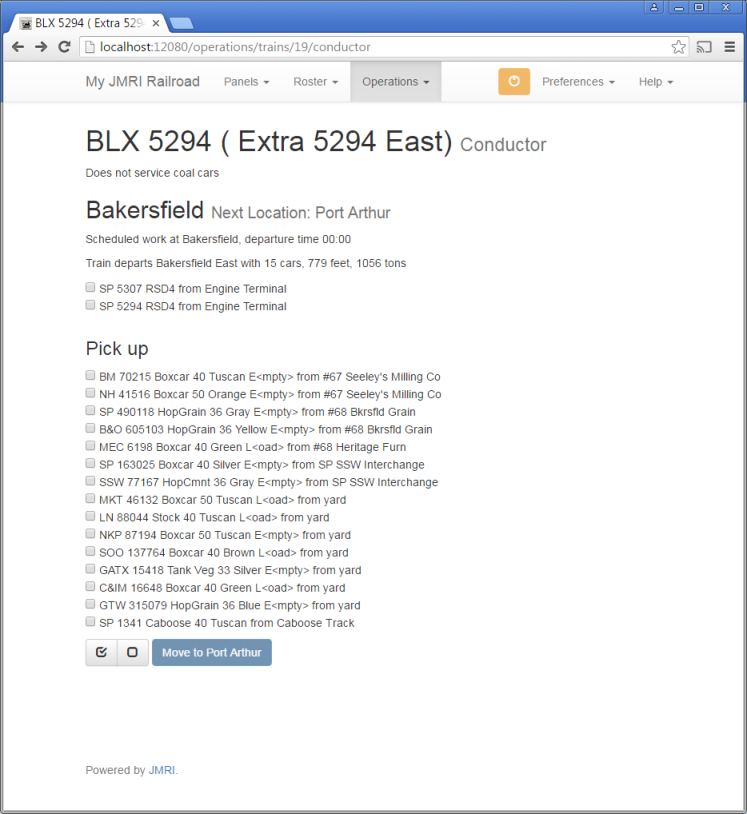

- Train Conductor

- Show Car Types Serviced (Diagnostic Tool)

- Print or Preview

- Print or Preview Manifest

- Print or Preview Build Report

- Print or Preview Saved Train Manifests

- Print or Preview Saved Build Report

- Train Build Options

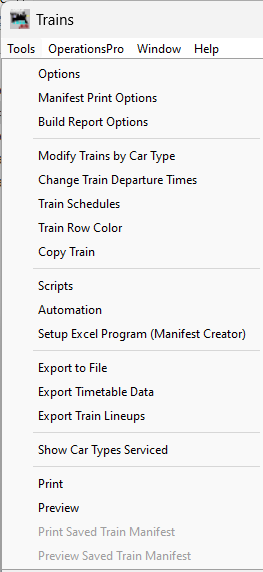

- Trains Tools

- Options

- Manifest Print Options

- Build Report Options

- Modify Trains by Car Type

- Change Train Departure Times

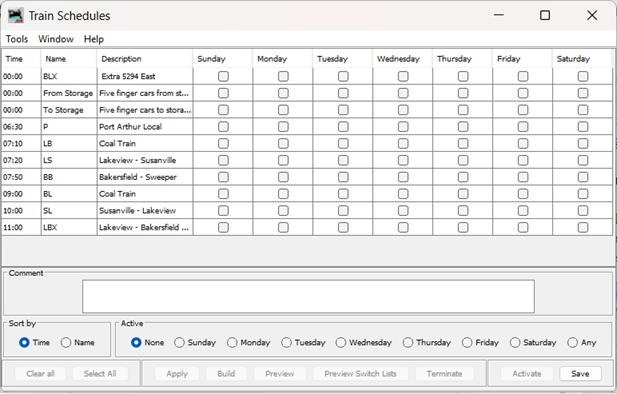

- Train Schedules

- Train Row Color

- Copy Train

- Train Scripts

- Automation

- Setup Excel Program (Manifest Creator)

- Export to File

- Export Timetable Data

- Export Train Lineups

- Show Car Types Serviced (Diagnostic Tool)

- Print or Preview

- Print or Preview Saved Train Manifests

- Switcher Service (Local)

- Building Trains

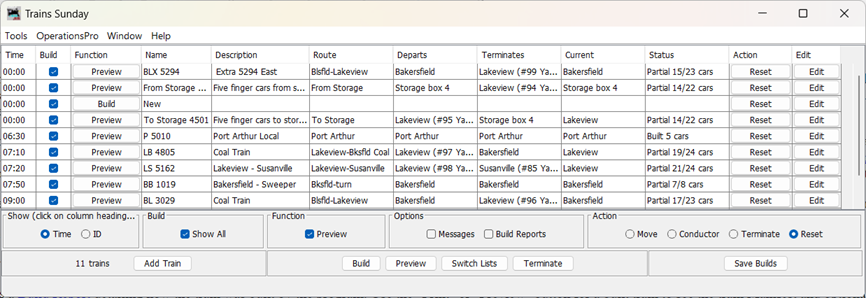

- Train Status

- Build Reports

- Problems Building Trains How to Fix

- Reading the Build Report

- Build Report Details (How Trains are Built)

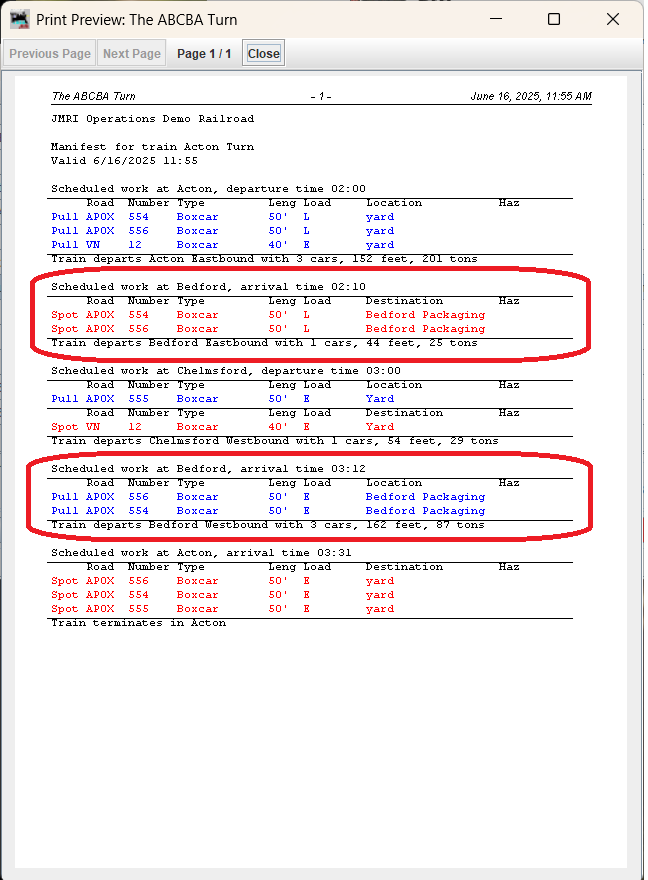

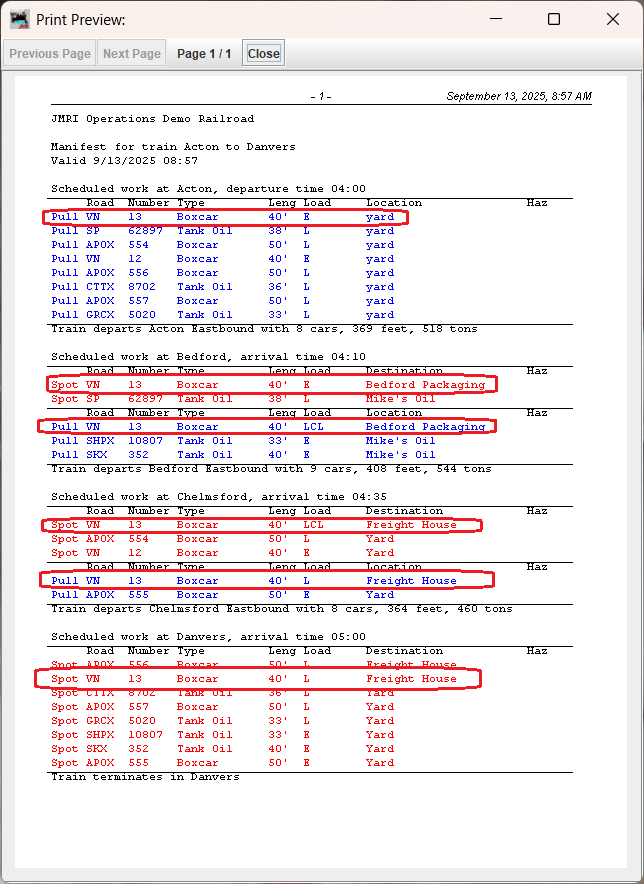

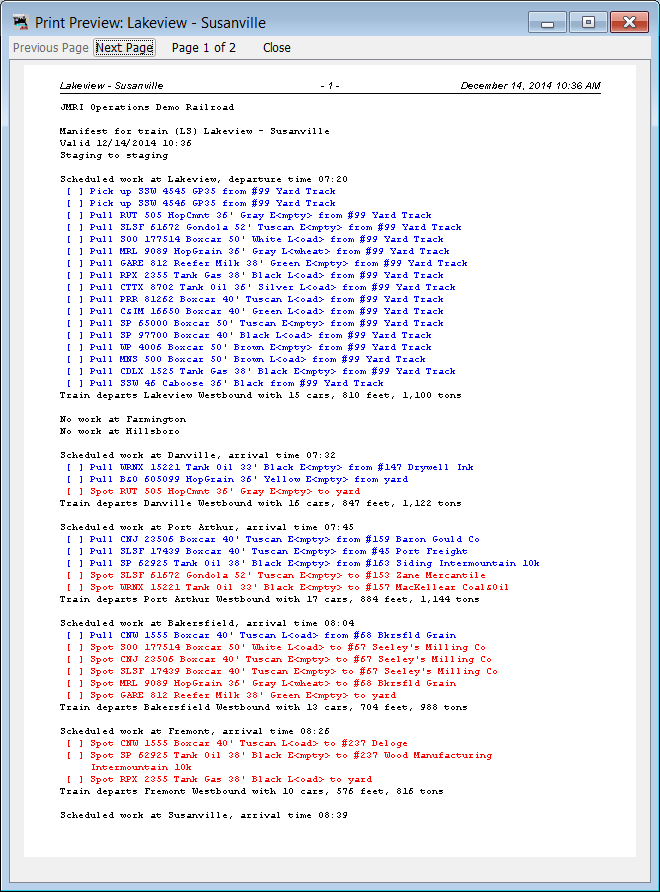

- Printing Manifests

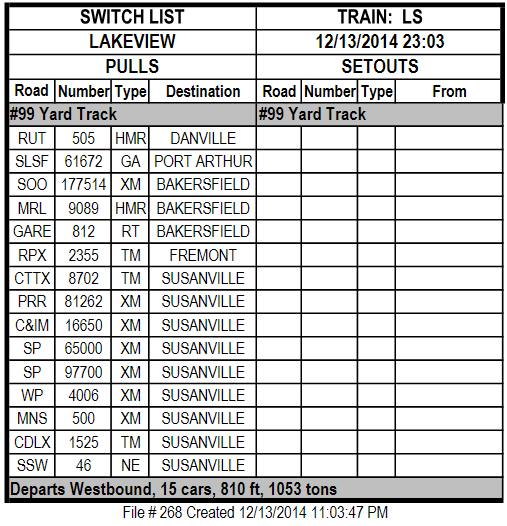

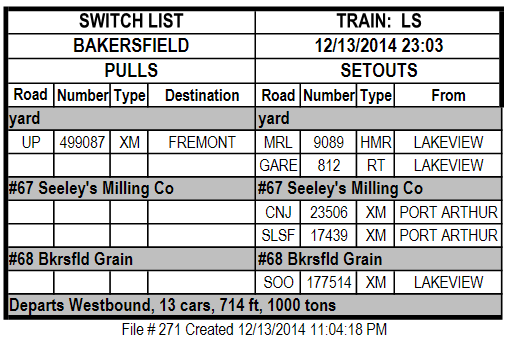

- Switch Lists

- Custom Switch Lists

- Moving Trains

- Terminate Train

- Save Builds

- Building Multiple Trains for a Session

- Operation Windows

- Operations Web Access

New User Advice

OperationsPro™ has been designed to create car movements that make sense to you and your crew. There are many options and features that the program provides and it can be a bit overwhelming, but you can get started by simply following the steps in the Quick Start Help. If you've never used a computer program to generate a train Manifest or switch list, we recommend that you load and use the demo files provided. Please read the build reports for the demo trains in very detailed mode, even if they build which they should since they are demo files. You should make changes to the demo database and see what the results are. This is your chance to experiment with the program before you enter your own data. You might want to print and save a demo train Manifest and build report for later reference.After playing with the demo files, you can reset the database and begin entering your own data. We strongly recommend that you get your trains to build to your liking without the use of staging tracks, classification/interchange tracks, and especially schedules and custom loads. We find that users attempting to use the advanced features before they understand how the program works tend to need a lot of help getting the car movement they desire. So start off small and get your trains to build correctly, read the build reports in the very detailed mode for your trains, even if they build to your liking. You need to get proficient with the build reports before you begin using the more advanced features of the OperationsPro™. Once you get your trains to build correctly, you can add staging tracks if you've designed staging into your layout. The other three advanced features are completely optional and aren't needed for good car movement. The next track type to experiment with could be Classification/Interchange Tracks. Once you get classification/interchange tracks to work correctly, you could then introduce Schedules for your industries and custom loads for your cars. If you do decide to use schedules, the first thing to understand is that you don't need schedules for all of your industries. So again start off small and only do a couple of industries and see what the results are. Adding schedules can not increase car movement, and in most cases will reduce car movement! So our advice is start off using the basic features of the program and later once you get good car movement, try the more advanced features.

One question that comes up often, is whether to enter the arrival and departure tracks into the operations program, and the simple answer is that you don't need to enter them into the program. Although it is possible to specify the A/D tracks in the program, it complicates the car movement by requiring an "extra" session to move the car from arrival track to the car's destination, and from the car's origin track to the departure track. Most find that allowing the program to pull a car directly from a train sitting on the "arrival" track and eventually spot the car to its destination, is the best method when using the program. Same goes when building a train using the "departure" track, car pulls directly into the train rather than to a specific departure track makes the operations run more smoothly. By not specifying the A/D tracks, you're letting your crew, and not the program, decide which tracks to use when servicing a train.

Display and Help

To adjust the display font size or appearance of the JMRI windows, select "Preferences..." found under "Edit" (on Windows/Linux) or PanelPro (on macOS) in the main window menu bar. The JMRI: Preferences Pane will appear with options to make Layout Connections, change the window Display appearance and font size, and many other settings including the Railroad Name. You can also configure JMRI to automatically open any of the operation windows on Start Up by adding a "Perform action".Most JMRI windows have as part of the menu bar the "Help" option. Select "Window Help.." to get information about the window you're using. Detailed step by step JMRI Operations How-To Instructions are available on the JMRI.org site.

British Railways

OperationsPro™ supports an alternate set of railway terminology for our British modelers. To use British terminologies, change the JMRI Display Locale to English (United Kingdom). With British terminology, trains travel Up/Down and East/West, and some British railway names and wagon types are provided to get you started.Multiple Layout Support

You can create and manage multiple layouts using OperationsPro™. From the main menu bar under "Edit" select "Preferences..." then "Config Profiles". Create a new Configuration Profile for each layout that you want to manage. The database for each layout is unique and not shared with the other layouts. You can find each set of operation files under JMRI⇒ "profile name" ⇒ operations.Operations Files

OperationsPro™ uses up to six XML files to store the operations database. You can find these files by selecting from the main menu bar, Help⇒File Locations, a new window should appear showing where your JMRI user files are. The operation files are stored in a directory called "operations" located inside a directory that uses the name of your profile. Once you start entering your data into OperationsPro™, you can find up to six operation files, and six identically named backup files. The operation files use the .xml extension, and the backup files have the .bak extension appended to them. These files are created when needed, for example the "OperationsEngineRoster.xml" file is created when you enter your first locomotive into OperationsPro™. The .bak back-up files are created when you make a change to one of the operation files.The program automatically loads the necessary files when you open one of the six major operations windows found under the menu bar "OperationsPro".

| File Name | Contains |

|---|---|

| Operations.xml | Settings |

| OperationsCarRoster.xml | Car database |

| OperationsEngineRoster.xml | Locomotive database |

| OperationsLocationRoster.xml | Location database |

| OperationsRouteRoster.xml | Route database |

| OperationsTrainRoster.xml | Train database |

Operations Demo Files

The operations program provides a set of demo files to help introduce you to the some of the features and capabilities of this program. To load the demo files, first open the Operations Settings window "Tools⇒Operations⇒Settings", and in the upper left corner of the Setting window is the "Tools" menu, select "Load Demo Files". The program will create a backup of your current configuration if you have one, and then loads the demo files. Restart JMRI to complete the demo load process.The demo program also supplies a simple panel to show how the train icons work. Load the panel before building the trains by selecting from the main JMRI menu, "File⇒Load table content and panels..." a window should appear and open the "operations" directory and then select the "Operations Demo Panel.xml" file.

Quick Start Help

From the main menu bar for JMRI find the "Tools⇒Operations" menu. There are six items in this menu. We recommend that you start with Settings and work your way down to Trains.So let's begin with the Settings window. Enter a name for your railroad, select the scale that you're modeling, and decide of you're are going to use descriptive names or AAR codes for your rolling stock. You can also optionally select which directions your railroad travels. You also have the option to add the OperationsPro™ menu to the main window. Select "Add Operations Menu to Main Menu" if you want this option. The next time you start PanelPro the OperationsPro™ menu will appear. Leave the rest of the fields in the Settings window alone for now, you can always come back and change them later. Now press the "Save" button in the lower right corner and close the window by pressing the "X" in the upper right corner.

Now open the locations window. This window will allow you to enter the locations or stations that your trains will visit. If this is your first time using a computer generated car forwarding program, it is best to start off small and gradually work your way through the various options and features available. Start by entering only three or four locations with each location having only two or three tracks. You only need to specify tracks that will be worked by your crew. For example you might start with tracks that service your industries, this type of track is called a spur. The spur's length determines how many cars can be spotted there. For example a 44 foot long spur can hold one 40 foot car, due to car body size and couplers.

To add a location, press the "Add Location" button at the bottom of the Locations window. A new window should appear, enter the location's name and press "Add Location". Once you've created a location, you can select which type of track to add to the location. We recommend that when creating your locations that you first use spur and yard tracks, and try staging and classification/interchange tracks when you're more comfortable with how the program operates. Try to keep things simple and don't modify the location and track defaults by making them restrictive with regards to the type of cars or locomotives that they will service. Also, the track and location default is to allow a train to service the location and track by trains traveling in any direction. Don't change the defaults until you can successfully build trains to your liking.

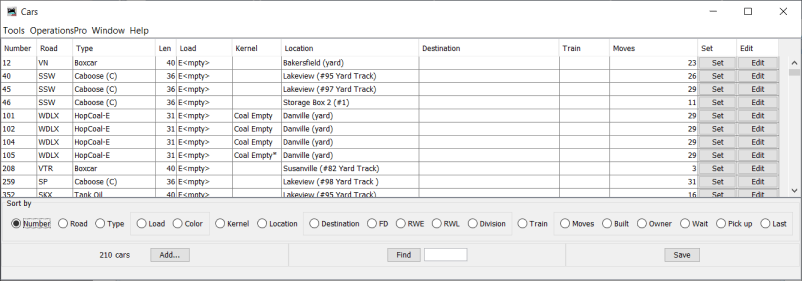

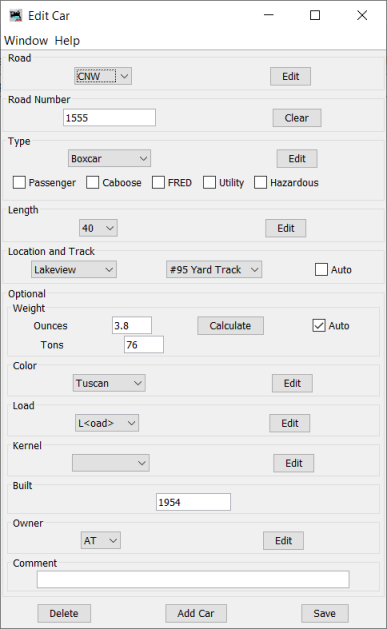

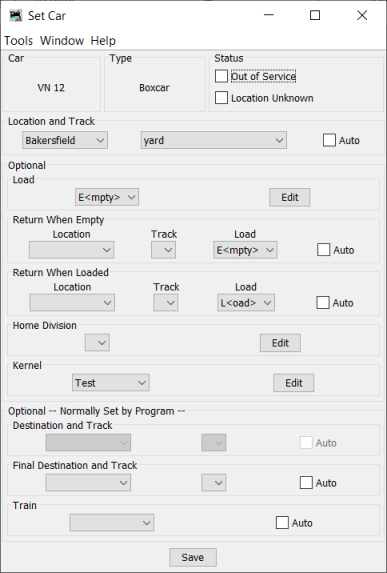

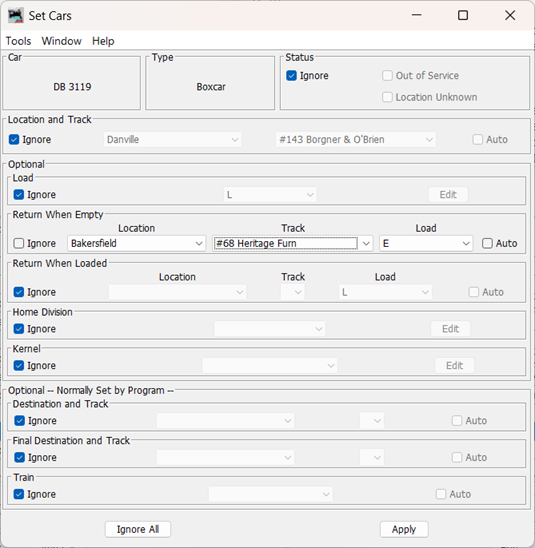

The next window to try is the cars window. This is where you enter or import from a file the non-powered rolling stock for your railroad. Press the "Add Car" button at the bottom left of the cars window and the Add Car window will appear. This window will allow you to enter cars into your operations database. Select the car's road name and enter the car's road number. Then select the car's type and body size under length. Press the "Add Car" button to create a new car, or to copy an existing one. Use the "Save" button to make changes to an existing car. Be sure to place the cars on a track using the "Location and Track" field found in either the add / edit car or set car window. The program works best if you keep at least 20% of your tracks empty, so don't place too many cars on tracks until you understand how the program builds trains.

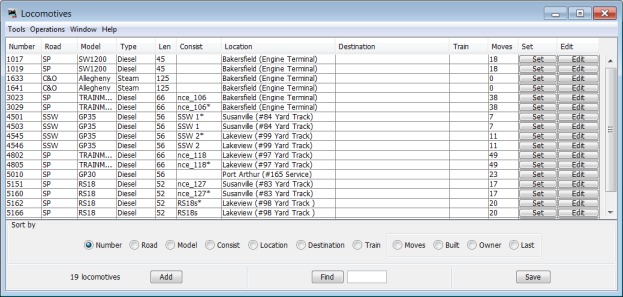

The locomotives window is similar to the cars window and allows you to enter or import locomotives for your trains. Entering and requiring locomotives for your trains is completely optional, and locomotives are not needed for the program to operate correctly. So if you want to manually assign your locomotives to your trains, don't bother entering the locomotive data into the program.

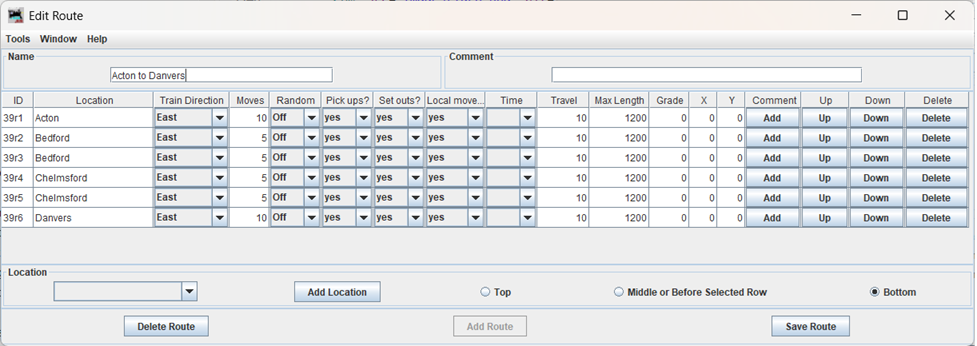

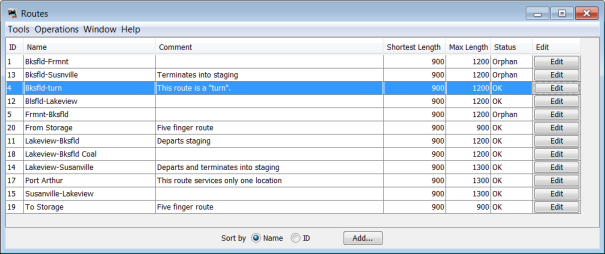

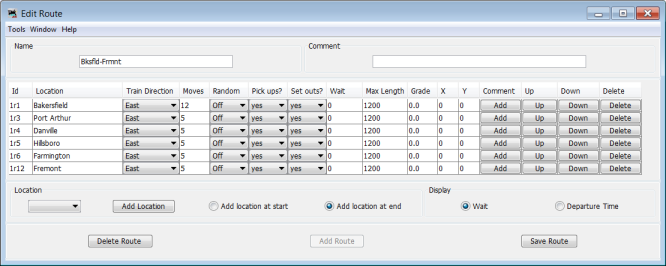

Now create a simple route for your first train to follow by pressing the "Add Route" button at the bottom of the Routes window. A new window called Add Route should appear. Enter a name for your route, and then press the "Add Route" button to enable the other fields. The first location you enter will be the departure location for your train, and the last will where the the train's terminates. Select a location from the lower left menu and then press the "Add Location" button in the window. Now select and add the next location your train will visit. Try and keep it simple by only entering each of your locations once in the route. And for now, don't modify the route in any way, later you can come back and modify how many cars are serviced at each location by adjusting the move count.

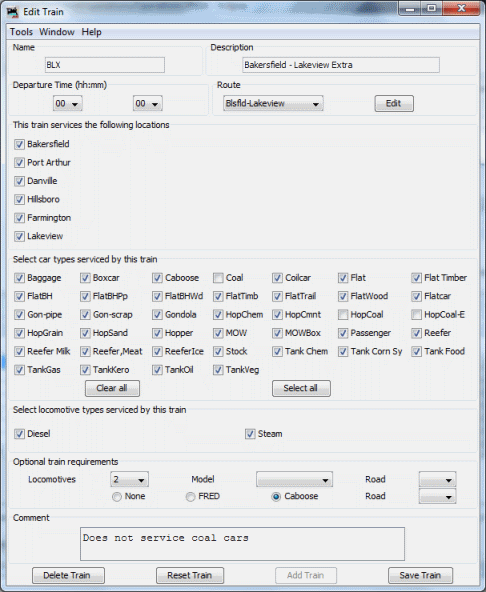

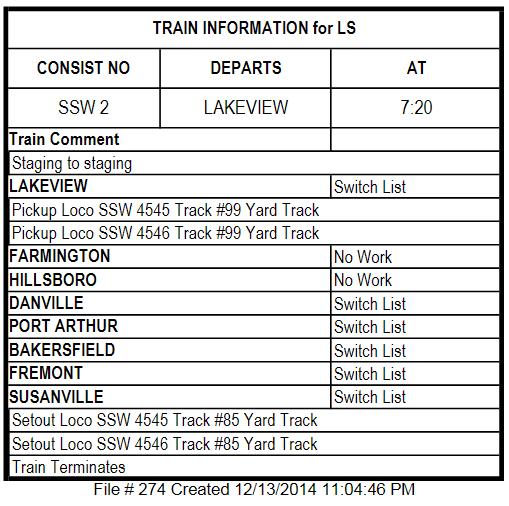

Now you're ready to create your first train by pressing the Add Train button at the bottom left of the Trains window. In the add train window, enter the train's name, followed by pressing the "Add Train" button. This will enable the other fields. Be sure to select the route you created for your first train, and press the "Save Train" button. Leave all of the train checkboxes alone which means the train will service all car and locomotive types. Leave the Optional locomotive requirements and Optional last car in train requirements for locomotives and caboose area alone for now. Close the add train window, and return to the Trains window. Press the Build button for the train. It should build. Now pressing the "Print" or "Preview" button will produce a Manifest for your train depending on the state of "Preview" checkbox at the bottom of the Trains window. Review the Manifest and you should see that the train serviced all car types. If you examine the Cars window you can see that cars are now assigned to your train. Once cars are assigned to a train, they are no longer available to other trains until the cars are delivered to their new location.

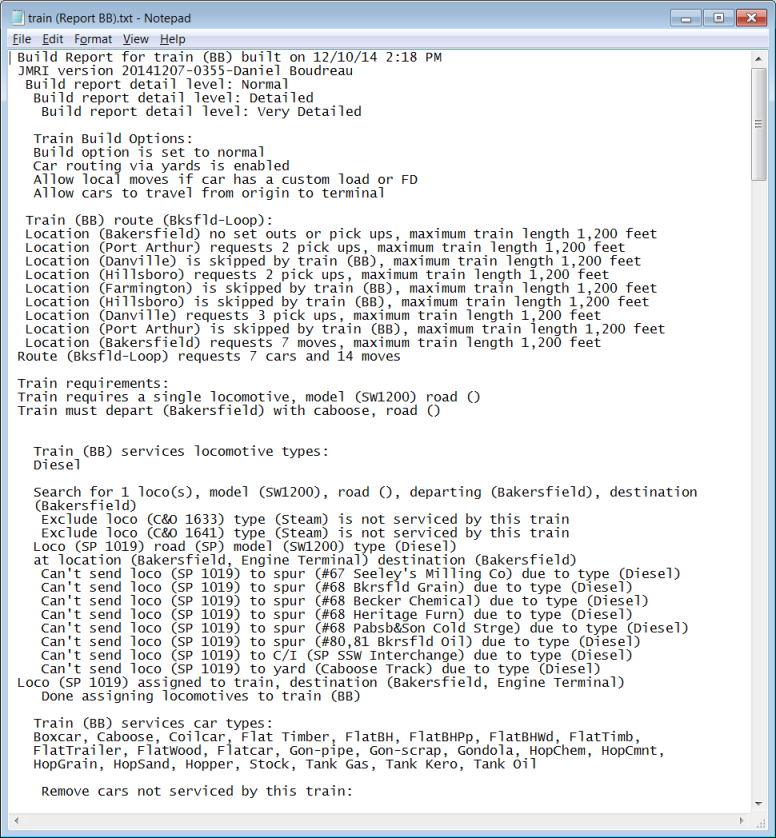

OperationsPro™ when building a train also produces a Build Report. The build report provides details on how the program built the train. It shows the available locomotives and cars found along the train's route, and how the program attempted to find destinations for them. When the program fails to build a train due to requirements requested by you, the build report can help determine what the issue was and how to correct.

Now try limiting the car types that the train will service by modifying some of the car types checkboxes in the Edit Train window. Use the train reset to release the cars that were assigned to the train so you can build it again without moving the train. With the new car types restriction in place, you should see that the train will only pick up and set out car types that are selected in the Edit Train window.

Now try restricting your tracks to only certain types of cars by modifying the car types serviced for a track. Now when you build the train, the train will only set out cars to tracks that are willing to accept them.

Press the Move button located in the Trains window and you will see that the train's location will change to the next in the route. You will also see that the Cars window will update to show the cars serviced by the train moving to their new location as the trains moves from location to location.

Now enter some locomotives into the operations database if you want the program to assign locomotives to your trains. Place some of your locomotives on a track located at the start of the route. Note that if you want two or more locomotives servicing your train, that the locomotives must be in a consist. Note that the last location in your route must have a track that will service the locomotive type or the build will fail. Now change the train requirements to require one or more locomotives.

If you want a caboose or car with FRED for your train, first configure some of the cars to be the last car in the train by selecting the "Caboose" or "FRED" checkbox in the Edit Car window. Now change the Optional last car in train requirements radio button to "Caboose" or "FRED" in the Edit Train window. Place the caboose on a track at the first location in your train's route. Be sure that the last location in your train's route has a track that will accept the caboose or the train will not build properly.

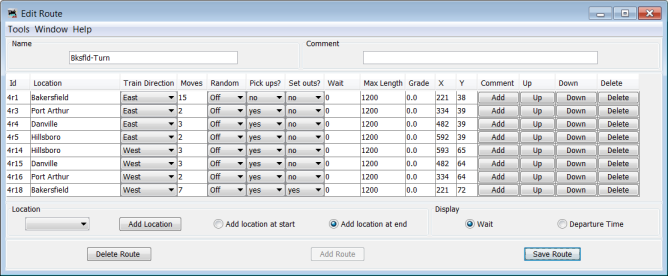

If you keep building your first train and moving it, eventually all of your cars will end up at the last location in your route! Create another route that is the inverse of your first train. Go to the Routes window and under the "Tools" menu select Copy Route. Select your original route, check the "Invert" checkbox, enter a name for this route, and then the "Copy" button. Now create a second train that uses this route to move cars in the opposite direction of your first train.

Once a car has been assigned to a train, it isn't available to other trains until the car is set out by either using the train Move or Terminate buttons. You also have the option of Building Multiple Trains for a Session.

The OperationsPro™ default mode for building trains is to pick up and set out cars to empty tracks. If you want to perform car swaps, pull cars from a track and replacing them with new ones, you need to change the Build Options to aggressive.

You should now be well on your way with regards to JMRI operations. Each window in OperationsPro™ has a "Help" item on the menu bar which will direct you to the section in this document that covers that window's capabilities. Many of the OperationsPro™ buttons and controls have popup tool tips, just hover your mouse pointer over the button to see the tool tip. Detailed step by step JMRI Operations How-To Instructions are available on the JMRI.org site. There's also OperationsPro Wiki that contains some useful information and insight into how the program works.

Help is also available at the JMRI users which is part of the Groups.io. Another good source for help is a series of articles written by David Haynes http://rcairgallery.com/stuff/Using-JMRI-Operations-A-Worked-Example.pdf. You can also view two excellent NMRA YouTube videos by Robert J Thomas Introduction to JMRI OPs For A Small Layout and Steve Todd - JMRI Operations with No Paper. There's also an excellent set of videos https://www.youtube.com/@dhtrainz4798 produced by David Hall using the Trainz Simulator and OperationsPro.

If you want to know more on how OperationsPro™ builds trains see the section on Build Reports.

And finally under the "Tools" item on the menu bar, you will find many useful functions, like the ability to print the contents of the window.

Trouble Shooting and Diagnostic Tools

The best tool for trouble shooting train build problems is the Train Build Report.If you want to determine which trains can service a location or track, use the the Show Trains Servicing this Location or Show Trains Servicing this track tools. The "Show trains Serving this track" tool can be found under "Tools" in the edit track menu bar. The tool also allows you to see how a specific car type will be serviced.

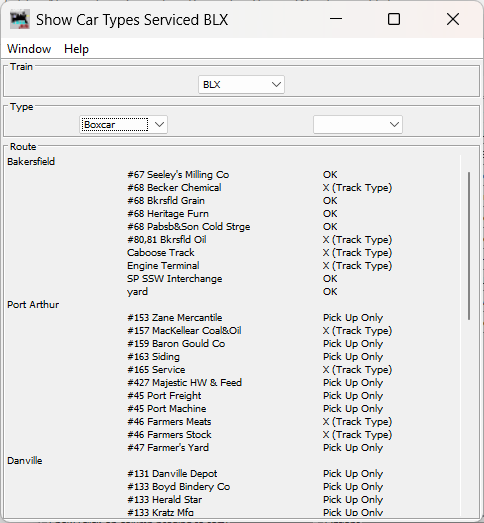

To understand which car types a train can service, and which tracks will accept those car types, use the Show Car Types Serviced tool.

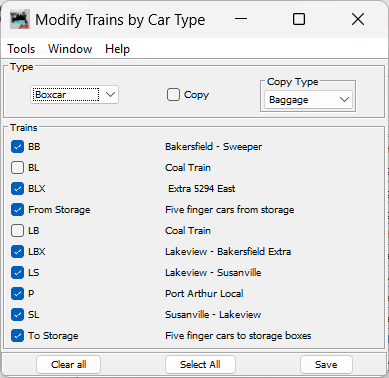

If you wish to see or modify which trains can service a car type, use the Modify Trains by Car Type tool found under "Tools" in the Trains window. Select the car type and you can quickly see and modify which trains can service that car type.

To review and modify which routes can service a location, you can use the Show Routes Servicing Location tool found under "Tools" in the Locations window.

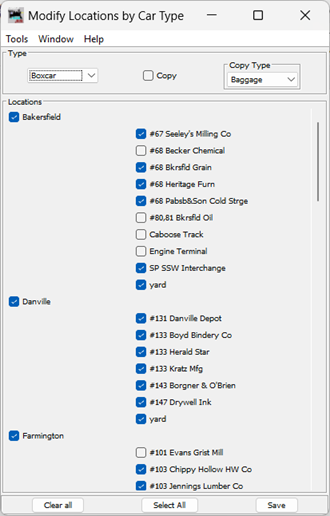

You can see or modify which locations or tracks can service a car type, use the Modify Locations by Car Type tool found under "Tools" in the Locations window.

There are several Print or Preview options under Location Tools that can be very useful. The first is "Print Location Details". This option will list each track for a location, and then details which car types, loads, roads, and trains can service that track. The "Track Analysis" option lists each car type, and then shows which tracks can service that car type. The analysis includes the total length of each car type, and then the percentage of track that can be consumed by that car type. To check for track configuration issues, select "Track Error Analysis" option. This option will check each track and determine if there's a train that will service the car types selected for that track.

If you decide to use schedules, the Show Schedules by Car Type and Load tool can show you which car types and loads will be serviced by your spurs. You can also see which loads will be generated out of staging to your spurs by using the Show Staging and Schedules by Car Type and Load tool.

To determine why a car isn't being routed correctly, you can use a train build report with the router set to "Detailed" or "Very Detailed". You can also use the Set Car tool found in the Cars window. You'll need to set the car's final destination to get a mini-build routing report.

If you restrict your classification/interchange tracks to specific destinations, there's a Check Destinations button that will confirm that your setup will not strand cars.

OperationsPro™ will send messages to the system console when there are errors or problems with the program. You can access the system console from any menu bar under "Help".

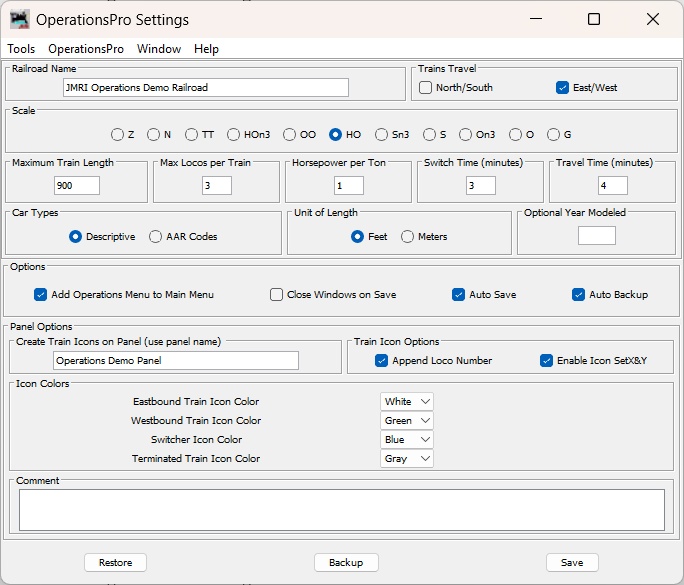

Settings

The Settings window contains general parameters for the Operations application. Select from the JMRI main window "Tools⇒Operations⇒Settings" to open the Settings window. The Settings window has fields and buttons to allow you to enter your railroad name, the directions your train's travel, the scale that you are using, printer and icon controls, and the ability to create backups and restore files for operations.

Railroad Name

Enter your railroad name in the field across from "Railroad Name". This name will show up on your Manifests. You can also have a different railroad name for every train in your roster, see Train Manifest Options for details.When you close the "Settings" window you will be prompted to make whatever railroad name you've entered to be the JMRI railroad name. You should answer "Yes" to the dialog window, this way all of the other applications in JMRI will reference the same railroad name. You can also change the railroad name by going to the JMRI: Preferences Pane found under "Edit⇒Preferences..." from the main menu bar.

Train Directions

If your railroad depicts trains traveling north and south select the "North/South" box, if your trains travel east and west select the "East/West" box. You must select at least one direction, and can if desired select both.Scale

Next select the scale you are modeling. This is useful when you enter the length of cars and tracks. You can enter the number of actual inches and the program will convert to scale feet. Append a double quote to the length when entering actual inches. The program will also automatically assign the proper NMRA weight for a car based on scale and length.Maximum Train Length

Enter the "Maximum Train Length" in feet or meters you desire for your trains. See "Unit of Length" below to select feet or meters. This field provides the maximum scale train length between stations. Later you can override this length if you wish a shorter train between any two locations. A 1000 foot train can carry approximately 20 cars, and is of course dependent on the car lengths assigned to the train.Note that if you increase the "Maximum Train Length" that it doesn't affect train routes that you've already created. Once you increase the maximum train length, you can manually increase the departure length of a train by editing the train's route. See Edit Route for more details.

If you decrease the "Maximum Train Length" the program will prompt you to modify your existing routes, and you can optionally have the program reduce all of your train's routes to the new shorter train length.

Maximum Number of Locomotives

Now set the maximum number of locomotives that you want the program to assign to a train. If you don't want the program assigning locomotives, set this value to 0.Horsepower per Ton

Enter the minimum horsepower per ton (HPT) that want for your trains when dynamically building a locomotive consist. Enter 0 if you don't want the program to consider the HPT or the train's route grades when building a consist.Switch and Travel Times

OperationsPro™ when generating switch lists for the various locations on your railroad, will estimate the arrival times for your trains based on the train's departure time and the switch and travel times. Enter the average number of minutes it takes to set out or pick up a car on your railroad. Then enter the average amount of time in minutes it takes to travel from one location to the another. Later when you create a route you will be able to increase or decrease the train's travel time between any two locations.Car Types

OperationsPro™ has two sets of car types for you to use. Descriptive provides type names like "Boxcar" and "Tank car", and AAR Codes provides type names like "XM" and "T" for boxcars and tank cars respectively. Select the one that you prefer. You can add or delete car types by using the car type edit window.Unit of Length

You can use scale feet or meters when entering the length of your rolling stock and tracks. The program can convert actual inches into scale feet when entering car, locomotive, or track lengths. Just append a double quote (") to any length. The program can also convert from actual centimeters to scale meters, just append "cm" to any length.Optional Year Modeled

You can optionally enter the year you want printed on your train Manifests.Add Operations Menu to Main Menu

When selected, add the operations menu to the main menu bar. The operations menu will appear the next time you restart JMRI.You can also automatically open any of the six operations windows when you start JMRI. From the main menu, under "Edit⇒Preferences..." select Start Up, and add a "Perform action" startup item for the desired window.

Close on Save

When selected, close operation windows when the "Save" button is pressed.Auto Save

When selected, the program will automatically save the operation files after they have been changed. When a change occurs the program will after 1 to 2 minutes automatically save the operations files. The program will also automatically save the operation files if you close the Trains window or shutdown JMRI.Auto Backup

When selected, the program will create a set of operation backup files each time the program is started. This is very useful when experimenting with the program, if you don't like what you've done, just restore one of the previous backups. See Backup and Restore for more information.Panel Options (Train Icons)

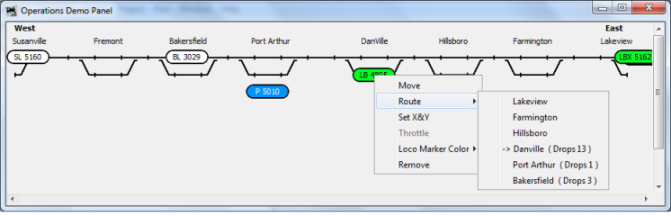

If you want the OperationsPro™ to place an icon representing the train on a panel, enter the panel's name (NOT the panel's file path name!), otherwise leave the name blank to disable. Load the panel using the main menu "File⇒Load table content and panels..." or use the Load table content and panels... option available in JMRI: Preferences Pane to load the panel at startup.The "Enable Icon SetX&Y" when selected allows you to teach the OperationsPro™ where to place the train icon on your panel when moving your train from location to location. Deselect this feature after your done teaching the program to prevent accidentally changing the train icon's position on your panel. If you also want the lead locomotive number as part of your train icon text and switch lists, select the "Append Loco Number" box. You can select the background color of your train icon depending on the train's direction. Select the color desired for each direction using the pull down menus. A switcher is a train with only one location in its route.

You can quickly set the train icon coordinates for your panel using "Tools" in the Routes and Edit Route windows.

The train icon menu allows you to "Move" a train to the next location in the train's route. You can also quickly move a train to any location in the train's route by selecting "Route" followed by any location in the route. The text for the move action becomes "Terminate" when the train arrives at the last location in the train's route. You would Terminate the train when all of the cars have been spotted to their specified tracks.

Comment

You can enter a comment for this set of OperationPro files. Useful when doing backups and restores allowing you to confirm that you have the correct set. The comment also appears on the train build reports.Save

When you're finished with the settings window, press the save button to store your settings in a file named "Operations.xml". You can find this file in JMRI⇒ "profile name" ⇒ operations. OperationsPro™ will also create a backup file "Operations.xml.bak" each time you press the save button.Backup

Copies of the operations files can be made to provide backups for both error recovery and for archiving. The data files used for operations is a set of six files and they are referred to as a "Backup Set". OperationsPro™ has two places that it uses to store these backup sets, referred to as the "Automatic Backup Store" and the "Manual Backup Store". These are stored under the JMRI "operations" directory in your home directory as "autobackups" and "backups". The purpose of the automatic backups is to make a copy of the files for "safe keeping" before changes are made to the main operations files. This way, if anything gets messed up, there is a copy of the last known good data that can easily be restored to undo the damage. In normal operation, an automatic backup is made each time OperationsPro™ starts (if the "Auto Backup" option is checked on the Settings window), and right before a Restore, Reset Database, or Load Demo Files operation is done.Manual backups are done only when the user requests it by either clicking the "Backup" button on the Settings window, or by selecting the "Backup" option from the "Tools" menu of the Operations Settings window. The Backup button will copy the files to the Manual Backup Store under the user's JMRI home directory as described above, while the Backup menu option will allow the user to specify any directory. This can be useful when making an archive copy that you want to move somewhere else for safekeeping.

All backup sets have a default name based on the date the backup was done, plus a sequence number, but this name can be changed to anything the user wants for Manual Backups. It is recommended that the names of backup sets made for archive purposes be given a meaningful name, especially if you are managing data for more than one railroad. For example, if today is August 29, 2012, the program will create a backup directory named "2012_08_29_00".

You can also select which directory to use for backups by selecting "Backup" from the "Tools" Menu.

What isn't backed up by OperationsPro™

There are many OperationPro directories and files that aren't backed up using the methods described above. You can find all of the directories and files not backed up inside the "operations" directory. Here's the list with the file types and directory names:

| File Type | Directory |

|---|---|

| Train Build Reports | buildstatus |

| Old Train Build Reports | buildStatusBackups |

| CSV Manifests | csvManifests |

| CSV SwitchLists | csvSwitchLists |

| json Manifests | jsonManifests |

| Log Files | logger |

| Train Manifests | manifests |

| Old Train Manifests | manifestBackups |

| SwitchLists | switchLists |

| Old SwitchLists | switchListsBackups |

Restore

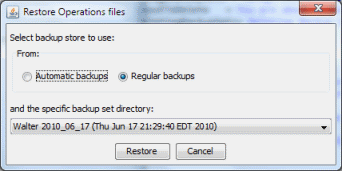

The program will automatically load the necessary operations files when one of the six major windows under OperationsPro is selected. If you wish to override the latest files use the Settings "Restore" button, or under "Tools" Restore.Note that restoring a Backup Set will overwrite the current operations files, therefore an Automatic Backup is done just before the restore copies the files, "just in case".

Backup Sets can be restored from either the Automatic Store or the Manual Store using the "Restore" button on the Settings window. Alternatively, the "Restore" menu option in the "Tools" menu of the Operations Settings window allows you to navigate to any directory, and would be used to restore an archived Backup Set.

The date and time that the Backup Set was made is displayed along with the set name to help distinguish the correct Backup Set.

You must quit and restart JMRI to complete the restoration of the operation files.

Settings Tools

Options

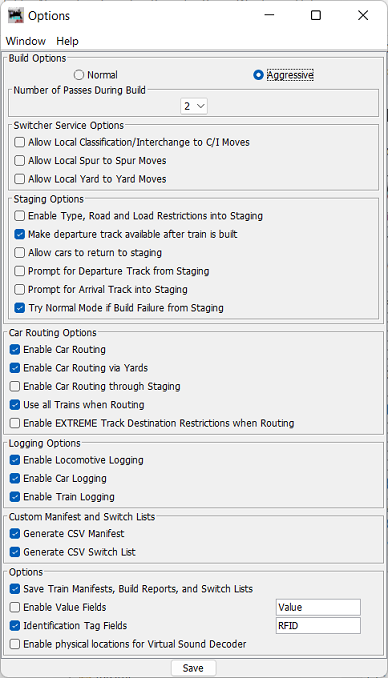

OperationsPro™ has several options that can be modified by selecting Operations⇒Settings⇒Tools⇒Options.

Build Options

There are three build train options, normal, aggressive and on time. Note that once you've built a train, the build option can not be changed until all trains are terminated or reset.Normal

It is recommended that you select normal when you first begin using OperationsPro™. Normal builds guarantee that when a car is delivered (set out) by a train that there will be track space available for the car. Normal mode will not fill every track to capacity which is more prototypical. However, normal mode won't swap a set of cars, cars are picked up or set out based on the available track space. Normal mode prevents track overloading. In aggressive mode you can "accidentally" create track overloading by the order you build and run your trains or by using the Train Reset function.

Aggressive

Aggressive builds makes the car's track space available as soon as a car is scheduled for a pick up. Therefore there can be instances where a train was to pick up a car to vacate the track, but a "later" train arrives early with a set out to that track and the car hasn't been picked up. However, more often than not the same train will perform the pick up and set out thus minimizing the number of conflicts. Aggressive also performs a multiple pass determination of car movements. The net effect is that more cars are moved within a given train, and complete car swaps can occur. Aggressive also tends to deliver cars to all of the available spurs. The smaller the spur, yard, or interchange the more likely that the program will assign cars to that track.

One serious consideration when using aggressive mode is that you can cause your tracks to be overloaded by selectively resetting your trains or building them and running them in a different order. Here's a simple example showing how it's possible to overload a track using the aggressive mode. Say you have two trains that will service the same track. The track has several cars on it, you build the first train and the Manifest shows to pull all of the cars from the track. You now build a second train, the program finds that the track will be vacated by the first train, so it schedules new cars to be spotted on to track by the second train. You later decide that you don't want to run the first train, and reset the train. Now the original cars on still sitting on the track, and you now run and terminate the second train. The program will deliver the new cars, while the old cars are still sitting there, which unfortunately will overload the track. You could also overload the track if you ran the second train before the first, the second train would try and deliver cars to the track that still has cars sitting on it.

To avoid overloading in aggressive mode, you also need to build, run, and terminate your trains in the same order. And do not use the train reset after you've built or terminated other trains! However, if you need to reset a train, you should also reset all of the trains built after the train that you want to reset, or live with possible track overloading. And never reset a train built before a train that you've already terminated. Normal mode will never overload a track, so you might consider using this mode if you find yourself having to reset trains or you want to build and run your trains in any order. The recommendation is not to use train reset in aggressive mode once you've built or terminated additional trains. And if you do reset a train, there isn't a guarantee that building the train again will pull the same cars, each train build can be different depending on the car movements created by the other trains.

On Time

On time is an experimental mode of operations that was introduced in January of 2026. On time mode requires the use of a real or fast clock to dictate train movement. To use on time, your trains must run on schedule. They should depart at the correct departure time, and they should complete their work reasonably close to the times provided on the train Manifests. When running OperationsPro in on time mode, tracks that have Quick Service enabled can be reused multiple times based on when cars are set out and picked up.After selecting the "On Time" radio button, a text field called "Dwell Time" is enabled. Dwell time is the number of extra minutes the program will use to determine when a track has available space, or when a car is available for pick up. For example, if a car is pulled at 1:30 PM and the dwell time is 60 minutes, the track space vacated by the car is available at 2:30 PM. For car pick ups, if a car is set out at 2:10 PM and the dwell time is 60 minutes, the car can be pulled by a train at or after 3:10. You would normally set the dwell time greater than your worst operator's completion time for a train. For example, if some of your operators normally finish their runs 30 minutes late, you would set the dwell time to 30 or more minutes. Dwell time helps prevent the frustration of not having the track space or car available from a previous train delivery. However, high dwell times will cause less cars to be moved in a given time.

To help troubleshoot timing problems with your cars using the on time mode, it is recommended that you show the "Last Train" on your Manifests and switch lists for car pick ups. This way if a car isn't found, you'll at least know which train was supposed to drop off the car. You should also enable train, car and engine logging, and Save Train Manifests, Build Reports, and Switch Lists

Number of Passes During Build

When building trains in aggressive mode, you can control the number of passes the program performs. Two passes is the default, and for most users is the correct value. The program works best when there's space for cars on the layout, and two passes should provide good car movement. If your layout is more towards the full side of the equation, increasing the number of passes could increase car movement. In most cases, three passes is more than adequate, and if your layout is jammed with cars, four passes might provide you with good car movement. The one major drawback to increasing the number of passes, is that your train build reports will be longer since each pass by the program is documented.Switcher Service Options (Local Car Movement with Default Loads)

The next three "Allow Local ..." options control car movements when using a switcher to service a location. A switcher only services one location. The three options only apply to cars with the default "E" or "L" load. Normally it is better not to allow a car to move from one spur directly to another spur at the same location when using a switcher. This type of move can be very unrealistic, picture moving a boxcar from a shoe manufacture directly to an auto manufacture. Also moving a car from one yard track to another can have your crew wondering what kind of busy work is being generated! We recommend that you leave all of the checkboxes unselected, but if you need these types of moves for cars without a final destination or custom load, select the appropriate checkbox.You should note that schedules and custom loads can override the switcher options. So if you need certain car movements for a switcher, it's best to use schedules to define them. Also see Allow local moves when a car has a custom load or FD.

Staging Options

Enable Type, Road and Load Restrictions into Staging

This option restricts trains to staging tracks that only accept the train's rolling stock type, road and load names. When "Enable Type, Road and Load Restrictions into Staging" is selected, the program will only deliver a train to a staging track has the same rolling stock, road and load name restrictions. This is useful when you want trains delivered to staging tracks based on the train's rolling stock preferences. However, if you want certain car types, car roads, or load names to be transported by a train, but not delivered to staging, deselect this option.If you specify a certain train or route to be accepted by a staging track, this option is ignored, and you can then control which car types, loads, and road are to be accepted by the staging track.

Make departure track available after train is built

This option when selected makes the departure track in staging available for other trains immediately after the departing train is built. For trains that return to the same staging location, this option allows the train to use the same track it departed on. This option is only available when using the aggressive mode for building trains.Allow cars to return to staging

When a train departs and returns to the same staging location, it is regarded as a turn by the program. A turn normally takes cars from staging, sets them out on the layout, picks up new cars and returns to staging with those cars. Normally the program doesn't allow the same cars to depart and return to staging. However, it may be desirable to allow the train carry the cars rather than having the program report that cars in staging couldn't be delivered to destinations on the layout. Selecting this option allows a turn to transport cars to and from the same staging location. Note that when this options is selected, that the program will only return cars to staging when destinations are not available on the layout.It is recommended that you leave this option disabled, as it's also available on a per train basis. See Train Build Options. Note that when this option is enabled, the program may have difficulties swapping cars from staging and the layout as the program must assume that all cars in staging could return to staging.

Prompt for Departure Track from Staging

If you would like the program to ask you which track a train should depart from staging during the train build, select this option. Normally during the train build the program would select the track with the least amount of use when determining which track to depart from. Note that the program will only prompt you if there are two or more trains available in staging that meet the train's requirements.Prompt for Arrival Track into Staging

If you would like the program to ask you which track a train should use when arriving into staging during the train build, select this option. Normally during the train build the program would select the track with the least amount of use when determining the track to arrive on. Note that the program will only prompt you if there are two or more tracks available in staging that meet the train's requirements.Try Normal Mode if Build Failure from Staging

When using aggressive mode to build a train, the program will first try and pull cars from all of the train's locations to free up space for cars departing staging. Sometimes this causes the length of the train to exceed the maximum length requirements of the route, causing a build failure. If this option is selected, and the build fails, the program will automatically try to build the train in normal mode. In Normal mode cars from staging are placed along the train's route before pulling cars from location, the exact opposite of aggressive mode.You can also request to build a specific train in normal mode, see Train Build Options.

Car Routing Options

Enable Car Routing

When car routing is enabled, the program can use multiple trains to deliver a car to its final destination. When car routing is disabled, the program will attempt to route the car using a single train. If it's not possible to route the car with a single train, the program will remove the car's final destination, and eventually send the car to a location/track that is configured to accept the car. The railroad division feature, RWE, RWL, and schedules use routing to move cars. With car routing enabled, you can use a Schedule to deliver a car to a specific location using the car's final destination fields. The car routing algorithm will search for the most efficient route for the car to travel. The router will attempt to use classification/interchange tracks and then optionally by yards to move cars. If you don't want to use yards when routing, you can deselect the Enable Car Routing via Yards checkbox. The program will try and find a route using a maximum of seven trains to complete the car move. Note that the program never gives up trying to route a car. If a car has been assigned a Final Destination or custom load the program will try and route the car during every train build that has access to the car. It is recommended that you leave car routing enabled.Enable Car Routing via Yards

The program when routing a car will first try to find classification/interchange tracks to move the car to its final destination. If you want the program to also consider using yard tracks when routing, select this option. It is recommended that you only use classification/interchange tracks when routing cars, and leave this option disabled.Enable Car Routing through Staging

Routing through staging is disabled by default. This is considered to be an advanced feature and shouldn't be used until you've become very familiar with the program. When enabled the program will try to route cars through staging if it couldn't find a route using C/I and yard tracks. Enabling this feature can significantly increase train build times. The router will only use staging tracks that don't modify a car's load. See Staging and Car loads. You must deselect all six car load controls for staging.You would allow routing through staging to create a virtual world outside of your layout. Now when you create a schedule, you can ship a car to a location and spur that exists outside of your layout. Staging is this case is the gateway to the virtual world. You can create one or several virtual trains to service the virtual world and the program will route cars to the industries you've created outside of your layout. You also have the option to only allow cars that are being routed to use the staging track.

Use all Trains when Routing

The option "Use all Trains when Routing" when selected instructs the program to use all of your trains to route a car. If you only want the router to use the trains that you've selected in the "Build" column of the Trains window, then deselect this option.Enable EXTREME Track Destination Restrictions when Routing

The last routing option "Enable EXTREME Track Destination Restrictions when Routing" is disabled by default, and is recommended that you leave it disabled. This option makes the track destination feature of a classification/interchange track more restrictive. When selected it tells the router to only use classification/interchange tracks that match a car's final destination AND the car's very next destination. Again, it is recommended that you leave this feature disabled, even if you've placed destination restrictions on your C/I tracks. When this feature is enabled, you must enter the destination AND the next destination needed to route a car to its final destination. For example, say the route for a car looks something like this: New York to Springfield to Worcester to Boston with each city hop requiring a separate train. In this case three trains are need to move the car from NY to Boston. With the "Enable EXTREME Track Destination Restrictions when Routing" disabled, which is the default, you only have to enter "Boston" as the destination for the departure C/I track in New York. The program when routing a car to Boston from New York, will determine that sending the car first to Springfield and then Worcester is okay because that's the route to get the car to Boston. However, if you enable this option, you must add Springfield in addition to Boston as valid destinations out of NY for the C/I track. The C/I track out of Springfield would need to allow destinations of Worcester and Boston. You would only use this feature if you needed to hard sort your cars by the car's next destination and final destination to specific C/I tracks.Logging Options

If you want the OperationsPro™ to log your locomotive, car, or train movements to a file, select the appropriate checkboxes. The program will create a new directory called "logger" in the operations directory. For each day's session the program will create a new file (.csv) using the day's date and the file will include all of the rolling stock movements for that day. Use a program like Microsoft Excel to view the file. The program will also create and maintain a separate file for each car's history and it can be also found in the "logger" directory in a second directory called "rollingStock".Custom Manifests and Switch Lists

Generate CSV Manifests

If you want to create your own Custom Manifest using a comma separated values (.csv) file, select this option. You can use a program like Excel to create a Manifest to your liking. Dan Foltz who is a JMRI user/programmer wrote the Excel based "Manifest Creator" and "Switch List Creator". You can find a copies of the programs at Manifest Creator - Add on to JMRI. There's also a Java based program written by Tim Mann called Model Railroad Switch List and Manifest Formatter that will create custom Manifests and switch lists for you using the CSV files.You can find the CSV Manifest files created by OperationsPro™ in the operations directory in a directory called "csvManifests". Each line of the file starts with a two to five letter code, followed by the code's description, and then any parameters associated with the code. Here's a list of the current codes and descriptions:

| Code | Description | Parameters |

|---|---|---|

| AH | Add Helpers | |

| AT | Arrival Time | Time |

| CC | Change Caboose | |

| CL | Change Locos | |

| DT | Departure Time | Time |

| DTR | Departure Time Route | Time |

| EDT | Estimated Departure Time | Time |

| HOLD | Hold Car | See PC or SC below, and note below |

| LC | Location Comment | Comment |

| LN | Location Name | Name |

| LOGO | Path name to logo | URL |

| NW | No Work | |

| PC | Pick up car | See below |

| PL | Pick up loco | See below |

| PRNTR | Printer Name | Name |

| RC | Route Comment | Comment |

| RLC | Route Location Comment | Comment |

| RH | Remove Helpers | |

| RN | Railroad Name | Name |

| SC | Set out car | See below |

| SL | Set out loco | See below |

| SMC | Search for Missing Car | See below |

| SMCM | Missing Car Message | Message |

| TKCB | Track Comment | Comment |

| TKCP | Track Comment Pick Up | Comment |

| TKCS | Track Comment Set Out | Comment |

| TC | Train Comment | Comment |

| TD | Train Departs | Name |

| TL | Train Length | Length, Empties, Number of cars |

| TM | Train Manifest Description | Description |

| TN | Train Name | Name |

| TRUN | Truncate | Appears if there's a switch list for the location and the "Truncate" checkbox is selected in the Manifest Print Options |

| TT | Train Terminates | Name |

| TW | Train Weight | Weight |

| VT | Valid | Month/Day/Year Time |

Time uses the format Hour:Minute.

The car parameters for pick up car (PC) and set out car (SC) are: road, number, type, length, load, color, location name, track name, destination name, destination track name, owner name, kernel name, car comment, pick up comment, set out comment, C, F, H, IDTag, RWE location name, RWE track name, U, utility car count, final destination name, final destination track name, load type, RWL location name, RWL track name, route path, division name, blocking order.

Where C = Caboose, F = FRED, H = Hazardous, and U = Utility.

The Search for Missing Car (SMC) parameters are identical to the above for (PC) or (SC).

The loco parameters for pick up loco (PL) and set out loco (SL) are: road, number, model, length, type, hp, location name, track name, destination name, destination track name, owner name, consist name, is lead loco in consist, loco comment, IDTag, DCC address, blocking order.

The program will include "Hold Car" for spurs and C/I tracks that are only serviced by one train. Configure the spur or C/I track option Select trains or routes for car pick ups to "Trains" and only select one train.

Generate CSV Switch Lists

You can also generate custom switch lists using a comma separated values (.csv) files. You can find the switch list files in the operations directory in a directory called "csvSwitchLists". The CSV switch lists use the same codes and descriptions as the CSV manifests, plus the following:| Code | Description | Parameters |

|---|---|---|

| SWL | Switch List | |

| DL | Departure Location Name | Name |

| ETA | Expected Time Arrival | Time |

| ETE | Estimated Time En route | Time |

| HOLD | Hold Car | See PC or SC above |

| NCPU | No Car Pick Up | |

| NCSO | No Car Set Out | |

| TA | Train Arrives | Direction |

| TDC | Train changes direction, departs | Direction |

| TIR | Train En Route | |

| TDONE | Train has already serviced this location | |

| VN | Visit Number | Number |

| END | End Switch List |

Options

Save Train Manifests, Build Reports, and Switch Lists

When the option "Save Train Manifests, Build Reports, and Switch Lists" is selected, OperationsPro™ will save the current train Manifest before creating a new one. The program will store the old Manifests in a directory called "manifestBackups" located in the "operations" directory. You can review your old Manifest using the Print or Preview Saved Train Manifests under "Tools" in the Trains or Edit Train windows.The program will also store a copy of each train's build report in a directory called "buildStatusBackups" also located in the "operations" directory. You can access old build reports from the Edit Train window under "Tools" Print or Preview Saved Build Report.

This option also makes backup copies of any switch list that you create. They are stored in a directory called "switchListBackups" located in the "operations" directory. A separate directory is created for each location's switch list that you create.

Enable Value Fields

You can use the value field to enter the value or cost of your rolling stock. You can rename the value field if you wish and use it for other purposes.Enable Identification Tag Fields [Settings⇒Tools⇒Options⇒[scroll to the bottom]

You can enable the assignment of reporters and tags for your locations and rolling stock. Reporters can be assigned to locations and tracks. When this option is enabled, the Cars and Locomotives windows will display the last location and time the rolling stock was detected. The Edit car and locomotive windows allow you to select an ID tag that has been entered into JMRI (scroll to bottom of "Optional" window frame). The Edit location and track windows allow you to select Reporters that you want to associate with them. You can rename the RFID field if you wish and use it for other purposes by changing the value on the Identification Tag Fields line.Enable physical locations for Virtual Sound Decoder

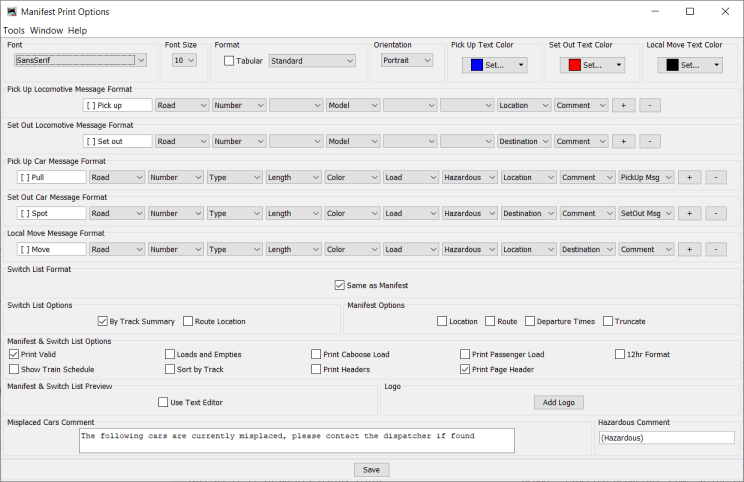

If you're using Virtual Sound Decoder, you can enter the physical coordinates of your locations by enabling this option.Manifest Print Options

You can modify the how OperationsPro™ prints the train Manifests and the location switch lists. From the "Operations⇒Settings⇒Tools" menu select "Manifest Print Options" to open the window. Press the "Save" button located at the bottom of the window to enable your changes. The "Save" button will also cause the program to update the Manifests for all trains that are built. This allows you to modify your Manifests without having to rebuild your trains. All of the text in the Manifest and switch list can be changed to your liking, see Manifest Print Options Tools below.

Manifest Printer Font

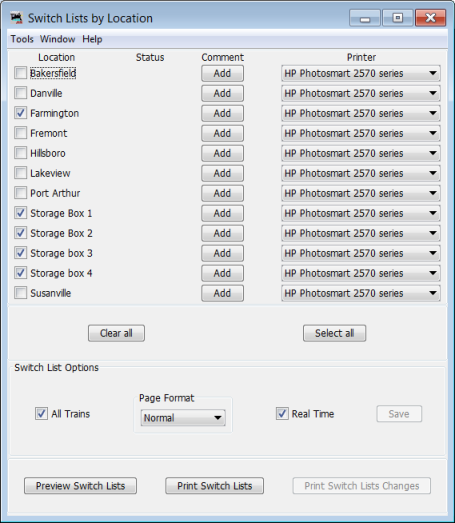

OperationsPro™ supports several types of fonts for printing. Select the desired font and size using the pull down menus. You can also select which printer to use when printing out a Manifest or switch list. See Switch Lists for more details.Format

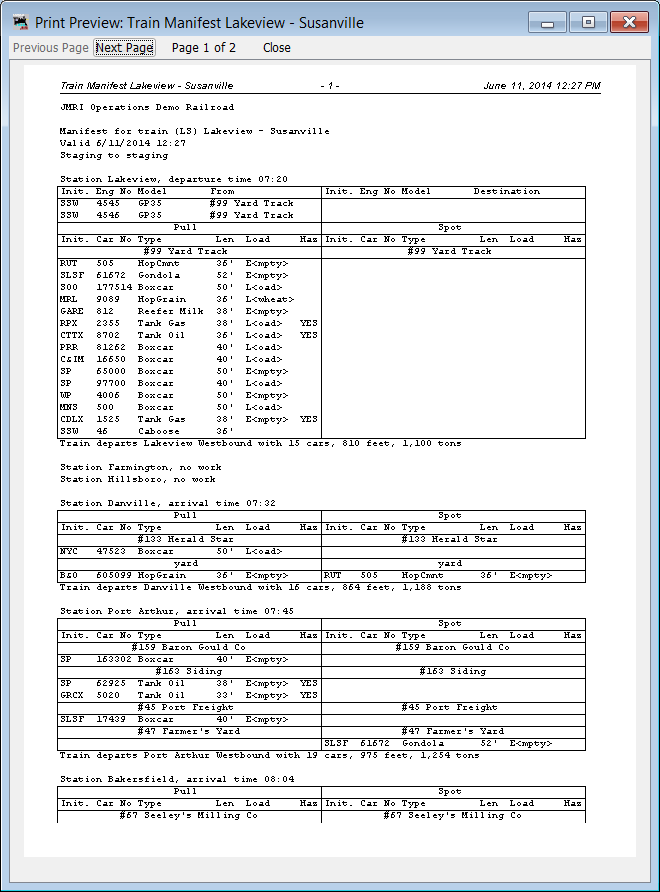

If you would like your Manifest and switch lists printed in a tabular (columns) format select the "Tabular" checkbox. The program uses the longest character length for each of the attribute's names (Road, Number, Type, Load, Hazardous, Color, Kernel, Owner, Division, Track, Location, Comment, Set Out and Pick Up Messages) to set the width of each column. Location names and track names can be up to 25 characters, so you might want to consider shorter length names when using the "Tabular" feature. FYI, the program reports the longest attribute names to the system console when creating Manifests. You can access the system console from any menu bar under "Help".There are three options with regards to how your Manifests and switch lists are formated. "Standard" provides one line for each car pick up or set out. The "Two Column" format creates Manifests with two major columns, the left column shows the car pick ups for a location, and the right column shows the set outs. The "Two Column" only uses half the page for the car information, so you might have to limit the number of car attributes (see Message Formats below) in order get the data to fit. The next format available is "Two Column (Track)". This format prints the track name in both columns in a header format.

The "Tabular" and "Two Column" formats use equally spaced fonts like "Courier New" or "Monospaced" so only equally spaced fonts are shown in the font selection box when either option is selected.

After selecting "Tabular" and pressing the "Save" button, you will find three additional "Tab" options at the end of the Message Format drop down menus. Use these three tabs to space out the Manifest or switch list to your liking. You can change the length of the tab characters if you wish, see Manifest Print Options Tools. Go to Printing Manifests to see examples of Manifests and switch lists using the described options.

Orientation and Paper Size

There are four options, Portrait, Landscape, 4.25 x 11 and 3.25 x 11. Paper size ("Letter" or "A4") is determined by the JMRI locale in use. To access the JMRI locale, from the main menu bar under "Edit" select "Preferences..." then "Display" and then select the "Locale" tab. Some printers require the English (United States) locale in order to print out a Manifest or switch list with the correct number of lines for paper size "Letter".Print on One or Two Sides

You have the option of printing your Manifest or switch lists on one side of the paper or both. Select "two sided long edge" or "two sided short edge" if you wish to print using both sides of your paper. Short edge means the pages are bound along the short edge of the page. Long edge means the pages are bound along the long edge of the page.Pick Up Locomotive Text Color

You can select the text color of your Manifest when the operation is to pick up a locomotive. Select the desired color from the drop down box.Set Out Locomotive Text Color

You can select the text color of your Manifest when the operation is to set out a locomotive. Select the desired color from the drop down box.Pick Up Car Text Color

You can select the text color of your Manifest when the operation is to pick up a car. Select the desired color from the drop down box.Set Out Car Text Color

You can select the text color of your Manifest when the operation is to set out a car. Select the desired color from the drop down box.Local Move Text Color

You can select the text color of your Manifest when the operation is to move a car from one track to another at the same location. The car in this case is not added to the train. Select the desired color from the drop down box.Message Formats

You can customize the pick up, set out, and local move messages for your Manifests and switch lists by selecting the appropriate drop down menus. To remove a loco or car attribute (Road, Number, Type, Length, Color, Load, etc.) select blank. You can also edit and or replace the "[ ] Set out", "[ ] Pick up" and "[ ] Move" prefixes. Two popular prefixes are "Spot" and "Pull" for set outs and pick ups respectively.For locomotive or car pick ups, the "Location" or "Track" attribute provides the track name where the rolling stock is currently residing. For set outs, the "Destination" or "Track" attribute specifies the track name where the rolling stock is to be eventually placed. The "Local Move Message Format" requires both the "Location" (where the car is) and "Destination" (where to spot the car) attributes. For local moves, you can substitute the "Track" attribute for the "Destination" attribute.

The program allows you to optionally display a pick up (PickUp Msg) or set out (SetOut Msg) message based on the car type and load. See Edit Car Loads "Optional Load Messages" for more info.

Switch List Format

You can use the same format for Manifest and switch lists, or you can customize the switch lists to your liking. Deselect the "Same as Manifest" if you want a different format for your switch lists.Manifests and Switch List Options

OperationsPro™ allows you to customize the text used in the train Manifest and switch lists to your liking. You can modify the Manifest or switch list text by using the "Edit Manifest Text" or "Edit Switch List Text" windows found under the Tools menu.Switch List Options

There are three checkboxes that allow you to modify the content of your switch lists. They are labeled "By Track Summary", "Route Location", and "Departure Time".The first option "By Track Summary" when selected, lists all car pick ups, set outs, and holds at a location by track and train. This summary is appended to the end of the switch list. This option is only available when you operate the switch list in Real Time.

You can include in your switch lists the train's route location comments by selecting the "Route Location" checkbox.

A switch list normally shows the estimated arrival time for a train. Selecting the "Departure Time" checkbox changes the format to showing the departure time.

Manifests Options

There are four checkboxes that allow you to modify the content of your Manifests. They are labeled "Location", "Route", "Departure Time", and "Truncate".Each location and the train's route can have an optional comment. The program will print these comments on your Manifest if the "Location" and "Route" checkboxes are selected respectively.

The Manifest normally shows the estimated arrival time for the train at each location worked by the train, selecting the "Departure Time" checkbox changes the format to showing the departure time. You can if you wish, print your Manifest without departure and arrival times. See Train Manifest Options for details.

The next option is "Truncate" and when selected will cause the program to reduce the amount of information printed when setting out or picking up a car at a location that also has a switch list. The idea here is that you have a location that is staffed by a crew member with a switch list and they will be doing the actual car pick up and set out for the train. Since the switch list contains all of the needed information with regards to where the cars are and eventually where they need to be, the train Manifest only shows which cars are being removed and added to the train.

Manifests and Switch List Options

There are twelve checkboxes that modify both Manifests and switch lists and are as follows:The "Print Valid" checkbox causes the program to print date and time the train was built, which isn't the same as when the Manifest was printed. The print time is shown at the top right of the Manifest or switch list when "Print Page Header" is selected.

If you want the Manifest and switch list to show how many car loads and empties are in the train, select the "Loads and Empties" checkbox.

If you want your local car moves to be grouped together for a location, select the "Group Moves" checkbox. Otherwise the program will list and mix the car set outs and local moves by the Track Blocking Order.

If you want your locomotive set outs to appear after your car set outs select the option "Print Loco Set Outs Last".

The default is not to show load names for caboose or passenger cars on your Manifests and switch lists, if however you want to see load names for those cars select the appropriate "Print Caboose Load" or "Print Passenger Load" checkboxes.

You can decide to use a 12 hour AM/PM rather than a 24 hour clock format for your Manifests and switch lists.

Selecting the "Show Train Schedule" prints which Train Train Schedule you are using when building your trains.

The next option is "Sort by Track". The program when creating a train Manifest normally lists the cars in the order they need to be placed into the train for proper blocking. The normal format is to list the cars in the order they will be set out as determined by the train's route, and then by the location's Track Blocking Order. If you would rather have the cars listed by the track name rather than blocking order, select the option "Sort by Track".

The option "No Page Breaks" when selected, prevents page breaks in a location's work for Manifests and switch lists. When printing, the program will determine if the work for a location can fix on the current page, and if not, will print the work on the next page. The program will only use page breaks if the work for a location won't fit on a single page.

The next option is "Print Headers". When this option is selected, the train Manifests and switch list will include a header showing all of the car attributes that you've selected in the above message formats. You can customize all of the header text by selecting "Edit Manifest Header Text" under the Tools menu.

The last option is "Print Page Header". When this option is selected, the train Manifests and switch list will have on the top of each page the train description, page number, and date the page was printed.

Manifest and Switch List Preview

If you want to use a text editor to preview your Manifests and switch lists, select this option. This option also allows you to make manual changes to your Manifests and switch lists before you print them.Add Logo

If you want a logo in the top right hand corner of your Manifests and switch lists, press the "Add Logo" button and select a file with the image you want to display. The supported image file extensions are .gif, .png, .jpg, plus others. You can also have a different logo for every train in your roster, see Train Manifest Options for details. If the Manifest or switch list text intrudes on your logo, you can adjust the start of the text by creating train comments for Manifests, and switch list comments for a location.Misplaced Cars Comment

OperationsPro™ provides a comment for your crew to search for misplaced cars. You can modify the comment to your liking. Full scale railroads unfortunately misplace cars as part of their operations, so having a few cars in the wrong place on your railroad is very prototypical. Save time and effort and let your operators find those misplaced cars for you.Hazardous Comment

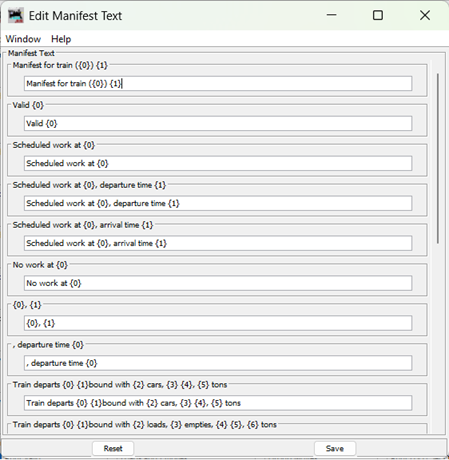

The program will add the "Hazardous Comment" to the Manifests and switch lists when a car has the Hazardous checkbox selected in the "Car Edit" window and the "Hazardous" message format is selected in the Manifest Print Options. The program will also add the "Hazardous Comment" if the car's load has been classified as hazardous. You can change the comment if desired, and press "Save" to keep the change.Manifest Print Options Tools

The menu bar of the "Manifest Print Options" provides additional features that can be found under "Tools". The first "More Print Options" allows you to adjust the length of the tab characters when using the Tabular feature.

Some of the text messages allow substitutions using the format "{number}". The program provides a tool tip when hovering over the text box which shows the available substitutions for that particular message.

You can also modify the color of the text by adding the color control text <FONT color="red"> at the start of the line, where "red" is the color text you want. Complete the color change by placing </FONT> at the end of the line.

Build Report Options

From the "Operations⇒Settings⇒Tools" or "Operations⇒Trains⇒Tools" menu select "Build Report Options" to open the build report options window.The program when building a train produces a build report for that train. The report contains details with regards to how the train was built and the various choices the program made when assigning cars to the train.

You can adjust the amount of information that the build report will show. Select one of the four levels using the radio buttons in the Build Report Options window. The program when generating the build reports stores the "Very Detailed" information to a file. The radio buttons control how much of that data is actually printed. The "Minimal" radio button provides the least amount of information and "Very Detailed" provides the most. If you're only interested why a train won't build, the "Minimal" setting might provide you with this information, but most likely not! The "Normal" setting shows the train's route and requirements, along with the choices the program makes for setting out locomotives and cars. The "Detailed" provides additional comments about the build and shows which cars were added to the train. The "Very Detailed" setting produces the most pages, and will show why cars are excluded from the train, and why they are not picked up or set out. Be sure and press "Save" after changing the build report selection.

For most users, the "Very Detailed" setting is the most appropriate when reading a train's build report and "Normal" for the router detail level. For information on the content of the build report please see Build Reports.

You also have the option of using a text editor to view your build report. A text editor can make trouble shooting a problem much easier for you. For example, say you have a car that isn't moving. Using the editor's find feature, you could search the build report using the car's road number and quickly find why the car isn't being picked up by the train. One of the tricks when using a text editor is to increase the number of characters per line by reducing the font size specified in the Build Report Options window.

The build report options window can also control the amount of information provided with regards to routing a car with a custom load or final destination. If you're not using schedules, leave the "Router Detail Level" option set to "Normal". You can change this option from "Normal" to "Detailed" or "Very Detailed" when you want to understand why a certain train or trains won't route a car. This set of radio buttons works differently than the "Detail Level" radio buttons in that it controls the amount of information created during the train build process. You will quickly find that the "Detailed" and "Very Detailed" modes can create many extra lines of text in the build report, and unless you have a routing issue, it is best to keep the "Router Detail Level" set to "Normal".

Backup

From the "Tools" menu in the Settings window, the backup option allows you to select any directory to save the operations files. See Backup for more information.Restore

From the "Tools" menu in the Settings window, the restore option allows you to navigate to any directory to restore the operations files. See Restore for more information.Manage Auto Backups

When "Auto Backup" in the Settings window is enabled, OperationsPro™ will create a backup of the operations files each time the program is started. To delete older obsolete files, use this tool.Load Demo files

See Operations Demo Files.Reset Database

To reset the operation database and remove all operation files, use the "Reset Database" option on the "Tools" menu of the Operations Settings window. An automatic backup copy of the current operation files will be made before deleting the main files. The results will be that the settings, cars, locomotives, locations, and trains files will be purged. Note that after this is done and JMRI restarts, the "Operations" menu item on the main menu will no longer be visible, as there are no operations files to load. If you want to once again use the operations feature, you can either load the demo files or restore a previous backup. To do this, open the Operations Settings page by selecting the "Settings" option in the Tools⇒Operations menu of the main page. From there you can do either a restore or a load of the demo files in the usual way.Locations

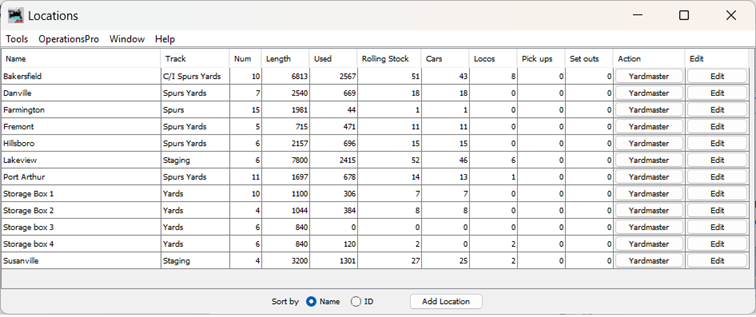

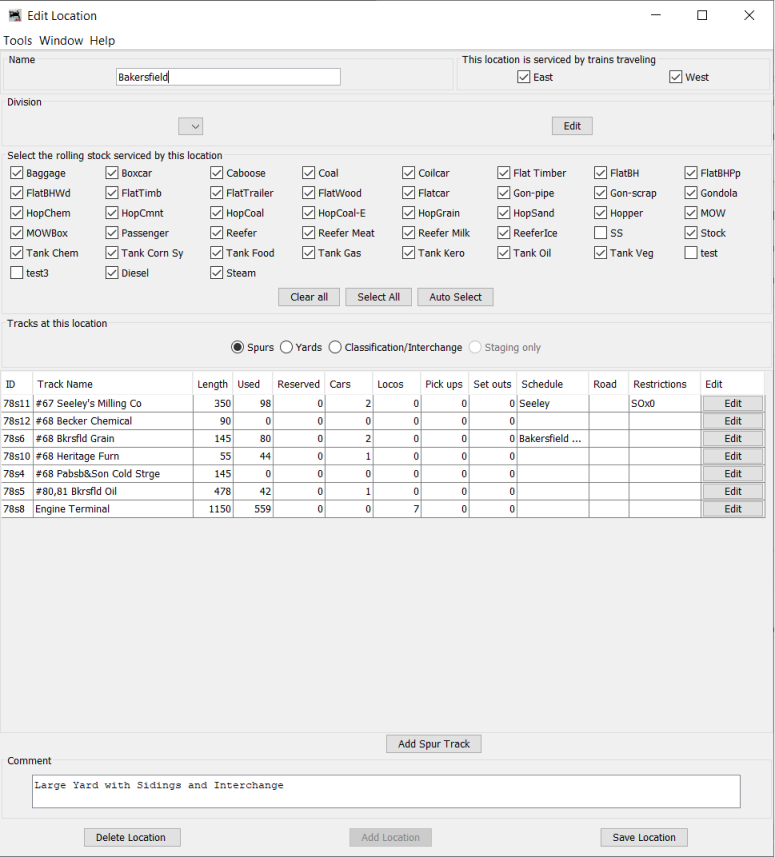

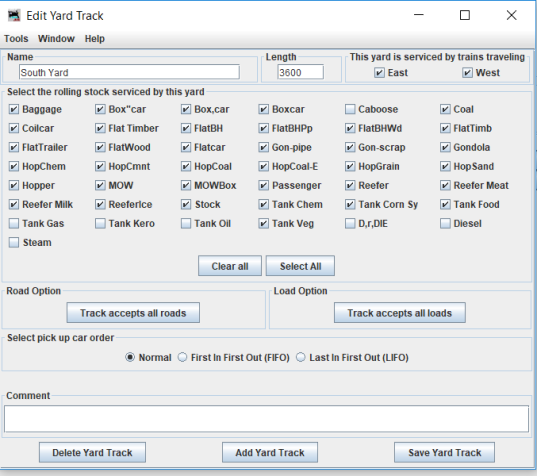

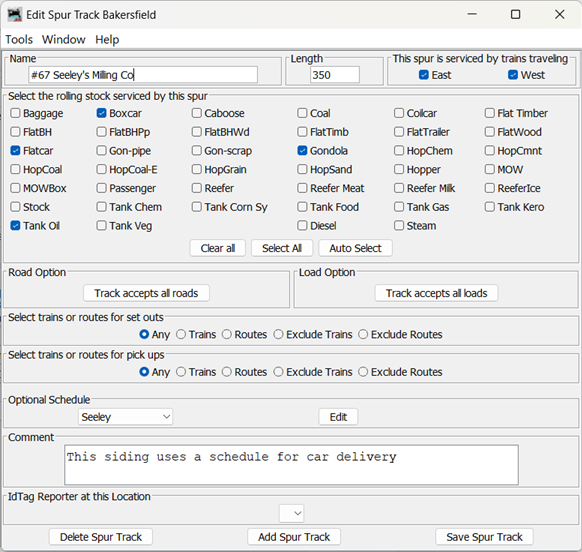

Locations are places on your railroad that trains visit to pick up or set out cars and locomotives. Locations can be cities, towns, stations, or just places where trains need to work cars. Select "Tools⇒Operations⇒Locations" to add or edit the locations on your railroad.